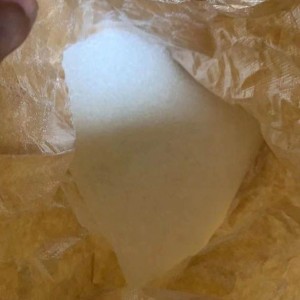

Ka ho khetha li-monomers tse ikhethileng, motho a ka fumana polyamide e hlakileng le e hlakileng ka ho sa feleng.Li-crystallite li nyenyane hoo li sa hasang khanya e bonahalang, 'me lintho tse bonahalang li bonahala li le pepenene mahlong a motho—e leng thepa e tsejoang e le microcry stallinity.Ka lebaka la khanya ea eona, sebopeho sa microcrystalline se boloka thepa ea bohlokoa joalo ka khatello ea khatello ea maikutlo - ntle le maru.Tekanyo ea kristale ha e na thuso, leha ho le joalo, hoo e se nang phello e mpe boitšoarong ba ho honyela ha likarolo tse bōpiloeng.E na le shrinkage e tšoanang ea isotropic joalo ka thepa ea amorphous.

Ke polyamide e nang le viscous e tlase, e bonaletsang ka ho sa feleng bakeng sa ho bopa ente.